Our product range also covers locking assemblies (clamping elements/locking device), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod ends and yokes.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant, farms, Construction works , Gear Coupling

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Black

- Application:

-

Mining Machiner

- Certification:

-

ISO9001:2008

- Surface Treatment:

-

Blackening

- Body Material:

-

45# Steel

- Name:

-

Cangzhou Tanso

- Size:

-

Customized Size

- Length:

-

Customized Size

- Product name:

-

gear teeth coupling

- Type:

-

Flexible Clamp Coupling

Supply Ability

- Supply Ability:

- 2000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- Packed in wooden cases

- Port

- Tianjin

-

Lead Time

: -

Quantity(Sets) 1 – 2000 2001 – 3000 >3000 Est. Time(days) 25 45 Our unparalleled research and development expertise is also reflected in our solutions: from low-backlash planetary gearboxes through servo right-angle gearboxes and complete drive units to EPG ® 5, our fundamentally redesigned sizing software. More than a million of our units are in use around the world – for example in machine tools and production systems, food and packaging machines, wood processing machines, robotics, transportation, automation and handling technologies.

To be negotiated

Online Customization

Product Description

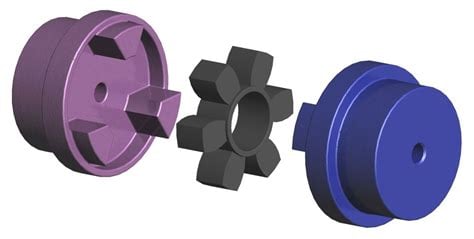

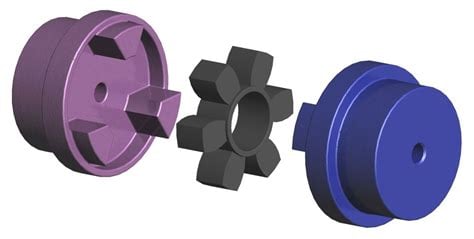

Introduction Of WGT Drum Gear Shaft Coupling With Middle Set

WGT Drum Gear Shaft Coupling With Middle Set divided into I type and II type two, WGT connected set of drumgear coupling type I with type WGT connected gland, a drum gear coupling type II without gland type.

WGT Drum Gear Shaft Coupling With Middle Set is an improved type of gear coupling, gear coupling can be compared with the straight allows larger angular displacement, can improve the tooth contact conditions, and improve the ability to transfer torque, prolong the service life, with angular displacement along the contact state of gear width, consisting of inner gear and the same number of teeth of the flange half band coupling parts etc..

When WGT is connected with the middle sleeve drum gear coupling, the relative angular displaceThe company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CAD/CAM system, industrial robot etc. ment of two shaft will occur when working. The relative periodic sliding of the inner and outer teeth will cause the relative sliding of the shaft, which will inevitably form the tooth wear and power consumption. Therefore, the gear coupling must work well and sealed. The toothed coupling has small radial size and large load capacity. I–Driven (outer) yoke same as drive yoke but is mounted on the implement. There are two types of shafts, domestic and metric, which are identifiable by their shapes. Domestic are generally one of four shapes: round, square, rectangle or splined. Metric are: bell, star or football shaped. In either case the primary (front) shaft is the same shape as the secondary shaft, only bigger so that the secondary shaft fits inside. This allows a telescoping effect to take place when the implement is raised on the 3 pt. or during a turning movement such as a bailer. All shafts have to be sized before use. Attach the implement to the 3 pt. and raise and support it. Attach the proper end to the tractor and attempt to attach the other to the implement. If the shaft is too long trim one of the shafts with a hack saw and try it again until it fits. This allows for the implement to be raised without binding. The shafts should overlap as much as allowed.t is usually used for shafting transmission under low speed and heavy load conditions. The high accuracy and dynamic balancing gear coupling can be used for high speed transmission.

Our Services

Pre-sale service

1 Satisfy your demands with professional and comprehensive pre-sales service.

2 Introduce the product categories.

3 Help users to chose the right product.

4 Analyzing the practical purpose and solve the difficult problems.

On-sale service

1 Review the contact, confirm the uncertainties and fix it through negotiations by both parties.

2 Assign production orders and arrange production as per requirements.

3 We promise to finish the good production quality and quantity guaranteed.

4 We are responsible to send the goods to the port.

After-sale service

1 Our servicemen will voluntarily answer your any question about the products.

2 If there is a quality problem of our products, we will follow the regulations to provide “three guarantees” services.

3 Upon receiving user’s complaints about the product, we will immediately dispatch personnel concerned to address problems.

4 High quality, Lowest price , Fast delivery, Perfect service after sale.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are manufacturer.

Q2:Do you provide samples ? is it free or extra ?

A: : Yes, we could offer the sample but not for free.Actually we have a very good price principle, when you make the bulk order then cost of sample will be return to you.

Q3: How long is your delivery time?

A: Generally it is 10-15 days if the goods are in stock. or it is 7-25 days if the goods are not in stock, it is according to quantity.

Q4:How long is your warranty?

A: Our Warranty is 12 month.

Q5 :Do you have inspection procedures for coupling ?

A:100% self-inspection before packing

Q6. What’s your payment?

A:1) 100% T/T. 2) 30% in advance, others before shipment. 3) L/C

Q7:Can I have a visit to your factory before the order?

A: Sure,welcome to visit our factory.

Packaging